CRITICAL EQUIPMENT

编号 :

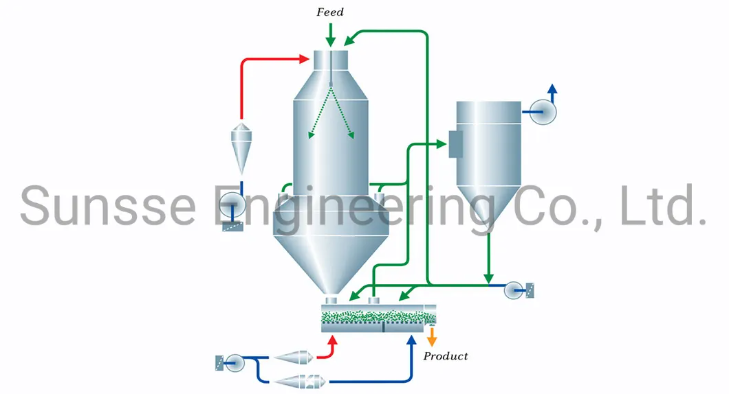

Spray dryer

零售价

市场价

keyword:

重量

库存

隐藏域元素占位

- Product description

- Features

- Application

-

I. Product Details

- Designed for High-Viscosity Materials (e.g., yeast slurry, enzyme preparations) and adaptable to extreme environments (-5°C to 47°C).

- Four-Stage Cyclone Separation + Fluidized Bed Secondary Drying ensures finished product moisture ≤4% and uniform particle size.

- Modular Structure supports quick installation and future upgrades.

II.Core advantage

The reason of choosing our spray dryer

- Intelligent Control: Siemens S7 - 300 PLC system, supporting remote monitoring and one - key start - stop.

It can monitor inlet air temperature, pressure and humidity in real - time, and store data in the cloud. - Energy - saving Design: Dual - stage system of condensate pre - heating + steam heating, reducing energy consumption by 20%.

The utilization rate of hot air circulation is ≥ 85%, reducing exhaust gas emissions. - Clean without Dead Angle: Fully automatic CIP cleaning system, with telescopic nozzles covering the tower body, pipelines and cyclone separators.

The cleaning time is shortened to 1 hour, and the downtime maintenance cost is reduced by 30%. - Flexible Production: Supports the switching between agglomeration/non - agglomeration modes to meet different customers' particle size requirements.

Modular design, which can be expanded to a production capacity of 5000 kg/h.

Applications and Benefits

Spray dryers are versatile pieces of equipment widely used in various industries, including food, pharmaceuticals, and chemicals. Their primary function is to convert liquid solutions or slurries into dry powders, which can enhance product stability, increase shelf life, and improve transportation efficiency. In the food industry, spray drying is commonly employed for the production of instant coffee, milk powders, and flavorings, allowing for the preservation of taste and nutritional value while eliminating moisture that could lead to spoilage.

The benefits of using a spray dryer extend beyond product quality. The process is highly efficient, reducing energy consumption and operational costs compared to traditional drying methods. Furthermore, the continuous operation of spray dryers allows for scalable production, accommodating both small-scale and large-scale manufacturing needs. By integrating advanced control systems and automation, manufacturers can optimize the drying process, ensuring consistent product quality and minimizing waste. Overall, the adaptability and efficiency of spray dryers make them an invaluable asset across multiple sectors, driving innovation and enhancing productivity in the manufacturing process.

III.Technical parameter

Category

Detailed Configuration

Processing Capacity

Evaporation capacity and production output customizable to user requirements. Feed Characteristics Viscosity ≤5,000 cP • Temperature: 60°C • pH range: 3.0–6.5

Finished Product Specs Moisture content: 4%–5% • Bulk density: 550–800 g/L • 80-mesh sieve residue ≤50%

Material Standards Contact surfaces: 304 stainless steel (thickness ≥3mm) • Internal weld polish: Ra ≤0.8μm

Safety Systems Explosion-proof door + automatic fire suppression + overheating alarm • Dust explosion protection rating: Ex IIB T4

IV. Service Support

From Inquiry to Delivery: Full - Process Escort

Service Process:

- Requirement Analysis: A professional technical team will make contact to customize exclusive solutions.

- Production and Quality Inspection: Conduct full - process supervision and provide material reports.

- Installation and Training: Send engineers for on - site installation and operation training.

- Worry - free After - sales Service: Offer a complete after - sales service to ensure smooth follow - up use.

-

Previous

Related Products

Product consultation

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!