MARKET APPLICATION

Market Application

06-08

06-08

What is citric acid?

06-08

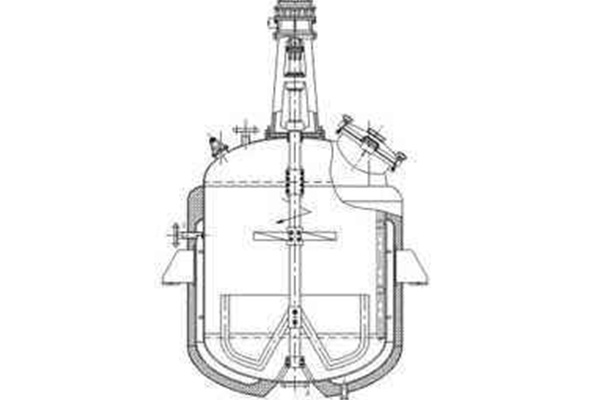

Structural properties of stainless steel reactor

06-08

The ultrafiltration concentrated skim milk and whey separation process is as follows

06-08

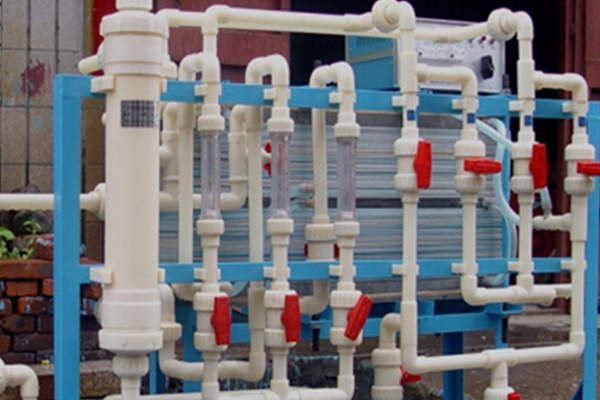

Ion Exchange System

06-08

The structure and working principle of the reactor

06-08

Technological factors of sticking to the wall of stainless steel reactor

06-08