CRITICAL EQUIPMENT

编号 :

Jet Cooker

零售价

市场价

keyword:

重量

库存

隐藏域元素占位

- Product description

- Features

- Application

-

A. Product Description

A steam jet cooker is a high-shear mixing and heating device where pressurized steam (typically 100‒200°C or higher) is injected directly into a liquid or slurry, often through a nozzle or chamber. The jet of steam rapidly heats the product while also mixing it thoroughly.B.Function

- Instantaneous Heating

The core function is rapid, uniform heating of materials to desire temperatures - often for genlatinzation or cooking.

- Gelatinization

In corn wet milling or starch precessing, it is used to cook the starch slurry at high temperatures (typically 105-130°C) to gelatinze the starch fully, a critical step before enzymatic hydrolysis.

- Shear Mixing

High-velocity steam flow helps achieve intense mixing, breaking down solid particles or agglomerates.

- Sterilization or Pasteurization

The high temperature can also kill bacteria or deactivate enzymes, depending on the application.

- Volume Expansion & Viscosity Control

It helps adjust the consistency or viscodity of slurryies bt breaking down solids during cooking.

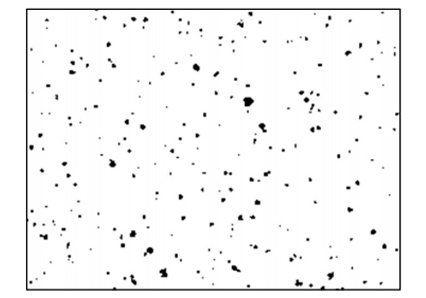

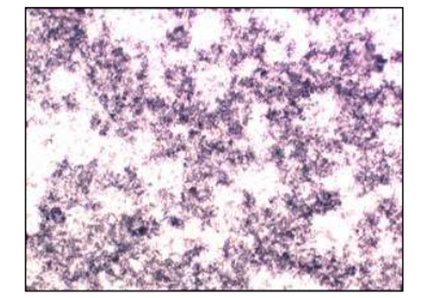

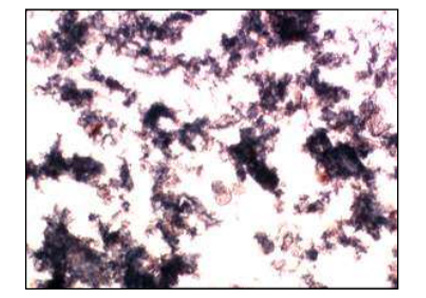

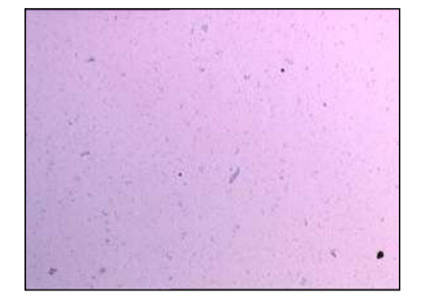

C.DIfference between the starch cooking quality

Uncooked starch

Well-cooked starch

Undercooked starch

Overcooked starch

D.Design of SUNSSE Jet Cooker

- Product paramenters

-

Advantages of Sunsse Jet Cooker

1. Excellent Liquefying Effect

The high-pressure steam jet cooker can generate high-intensity micro-turbulence during the liquefaction process. This leads to remarkable starch dispersion, with no insoluble starch particles and effective protein coagulation. Through jet liquefaction, the proteins are clearly aggregated and float on the liquid surface, significantly accelerating the speed of sugar filtration. It overcomes the drawback of dextrin remaining at the end of saccharification due to uneven heating of the material-liquid in interstitial liquefaction.

2. Continuous Jet Liquefaction with No Blockage

The high-pressure steam jet liquefier eliminates clogging fundamentally based on its structural principle. Even when there is whole rice or starch with a concentration of ≥30Be in the slurry, there is no clogging issue. The ejectors manufactured by our factory do not require disassembly and cleaning within 1 to 3 years of use. This resolves the frequent clogging problem that previously occurred with the jet liquefier due to the nozzle aperture, especially when used for superheated steam injection, which hindered continuous production.

3. Suitable for Low Pressure and Superheated Steam Injection Liquefaction

The jet liquefier utilizes steam as the driving force and is applicable not only to low-pressure steam but also to superheated steam jet liquefaction. When injecting liquefaction below 105ºC, a steam pressure of 0.2Mpa can meet the liquefaction requirements, and the steam and liquid are mixed evenly, enabling a savings of more than 15% of steam compared to the traditional liquefaction method.

4. Own Patented Technology

We possess our own intellectual property rights and patented technology regarding the jet cooker. We have a comprehensive system from design to production to ensure the quality of our products. This allows us to provide reliable and high-performance equipment to meet the diverse needs of customers in the relevant industries. Our patented technology also gives us a competitive edge, enabling us to continuously innovate and improve our products to better serve the market. -

A. Application

- Starch Cooking

- Biofuels

- Anaerobic Digestion

- Starch conversion

- General water heating

B. Industried Served

- Ethanol, Starches & Sweeteners

- Paper & Pulp

- Chemical

- Food &Beverage

Related Products

Product consultation

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!